We offer different styles of cup washers from basic cups to custom cup washers. These are available in stainless steel, brass and copper,

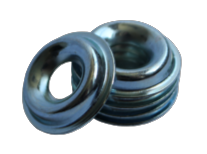

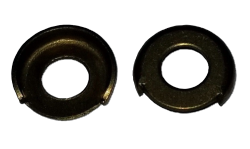

Basic Cup Washers

Basic or Standard Cup Washers have the sides of the cup or dish bent at roughly 90 degrees. The basic cup washers are manufactured in a shape that allows for a variety of uses in an array of applications. Standard cup washers are used to cover bolts or nuts for safety or anti-tampering requirements. Cup washers are also used to compress insulation and sealant materials. Additionally, they are also utilized as spring retainers.

With our self-contained tooling department utilizing the latest EDM and CNC equipment, we ensure precision manufacturing for every order, whether standard or custom.

| Material | Finish | Bolt Size (Metric) | Bolt Size (Standard) | Inside Diameter | Outside Diameter | Thickness | Quantity in Stock | Request a Quote | |

|---|---|---|---|---|---|---|---|---|---|

| View | Brass | Plain | 0.000 | 0.523 | 0.02 | 0 | Add to Quote | ||

| View | Brass | Plain | 0.000 | 0.523 | 0.02 | 990 | Add to Quote | ||

| View | Low Carbon Steel | Zinc & Clear | 0.000 | 1.000 | 0.074 | 0 | Add to Quote | ||

| View | Stainless Steel - 300 Series | Plain | 0.000 | 2.130 | 0.037 | 0 | Add to Quote | ||

| View | Brass | Plain | 0.000 | 0.682 | 0.03 | 24852 | Add to Quote | ||

| View | Aluminum | Plain | 0 | 0.078 | 0.920 | 0.025 | 530 | Add to Quote | |

| View | Aluminum | Plain | 0 | 0.078 | 0.920 | 0.025 | 1220 | Add to Quote | |

| View | Low Carbon Steel | Plain | 4 | 0.119 | 0.562 | 0.024 | 44001 | Add to Quote | |

| View | Low Carbon Steel | Zinc & Yellow | M3 | 4 | 0.127 | 1.194 | 0.032 | 71400 | Add to Quote |

| View | Low Carbon Steel | Zinc & Yellow | M3 | 4 | 0.128 | 0.495 | 0.02 | 67702 | Add to Quote |

| View | Brass | Plain | M3 | 4 | 0.129 | 0.420 | 0.016 | 0 | Add to Quote |

| View | Spring Steel | Plain | M3 | 5 | 0.140 | 0.580 | 0.021 | 4601 | Add to Quote |

Key Characteristics and Materials

The important characteristics of a basic or standard cup washer are different depending on the uses. The inside cup dimension, the outside dimension, the height, and the material thickness are factors to consider when designing your cup washer. Cup washers are available in materials such as Low Carbon Steel, Spring Steel, Stainless Steel, Brass, and Copper.

Basic or standard cup washers are available in finishes such as Zinc & Yellow, Zinc & Clear, Galvanized, Black Oxide, Nickel, and Phosphate & Oil. Choose a cup washer material and finish that meets your needs.

Benefits of Using Basic Cup Washers

Basic cup washers provide exceptional stability for fasteners, distributing load evenly to prevent damage and loosening. Thanks to our state of the art tooling department and advanced stamping equipment, our cup washers are always precisely manufactured. This helps to create a secure hold in high-vibration environments such as industrial machinery, automotive applications, and heavy equipment.

Their design helps protect surfaces from direct contact with fasteners, reducing wear and prolonging component life. Additionally, standard cup washers offer aesthetic benefits by concealing screw heads, creating a more polished and professional appearance.

When used with softer materials like wood or plastic, they prevent fasteners from pulling through or causing surface indentations. By leveraging CNC turning machines and specialized tooling, we produce custom cup washers that meet exact specifications, ensuring compatibility with a wide range of applications.

Extensive Product Selection

Basic cup washers are designed to accommodate a variety of bolt sizes and uses. We also offer other categories of washers such as clipped OD washers, D-shaped ID washers, slotted square washers, and fender washers.

Our catalog of machined parts, stampings, and washers are engineered with high-quality materials to meet your requirements. Our commitment to high-quality manufacturing allows us to provide custom solutions for unique applications, ensuring every washer meets exact performance requirements.

Industry Applications of Basic Cup Washers

Many industries depend on standard cup washers for structural reinforcement and component protection. The renewable energy sector, for example, uses these washers in wind turbines and solar panel mounting systems, where vibration resistance and durability are crucial.

The medical equipment industry also relies on basic cup washers to secure critical components in imaging machines, surgical tools, and diagnostic devices, ensuring safety and precision.

Get the Right Cup Washers for Your Application

Contact a specialist at Willie Washer to learn more about cup washers. Whether you need stock or custom parts, our team is ready to assist. Our warehouse contains over 8,000,000 pounds of raw material, ensuring quick turnaround times for both small and large production runs. Request a quote today to get started on your order and experience the precision and reliability of our basic cup washers.